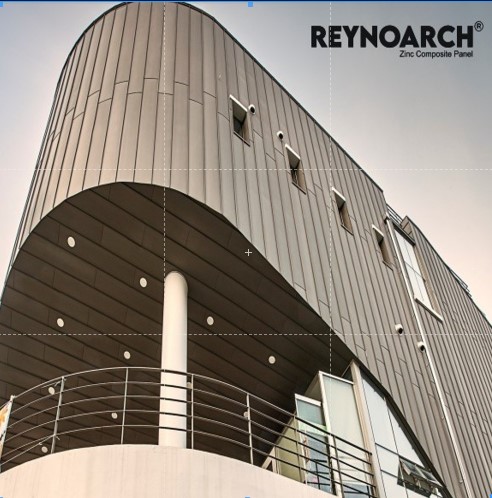

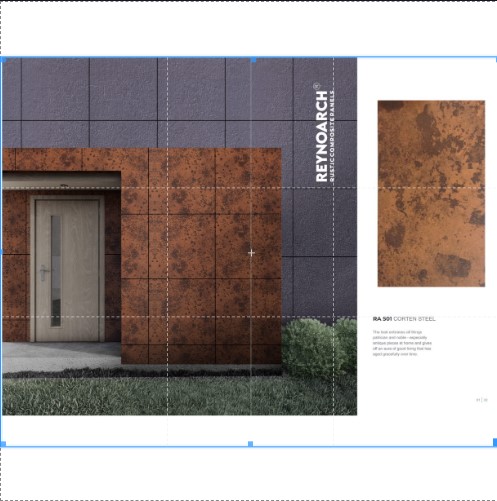

REYNOARCH ZINC COMPOSITE PANEL--QUARTZ ZINC Zinc Cladding Reynobond india

The shade formation of Natural Zinc through natural patina development over time also known by the term matte grey patina is called Quartz Zinc. When quartz zinc is scratched it heals on it's own with the spend of time.

Product manufacturer

Reynobond indiaProduct Category

Zinc Cladding

Reynobond india Zinc Cladding REYNOARCH ZINC COMPOSITE PANEL--QUARTZ ZINC

The shade formation of Natural Zinc through natural patina development over time also known by the term matte grey patina is called Quartz Zinc. When quartz zinc is scratched it heals on it's own with the spend of time.

Loading specs...

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Reynobond india

Reynobond india

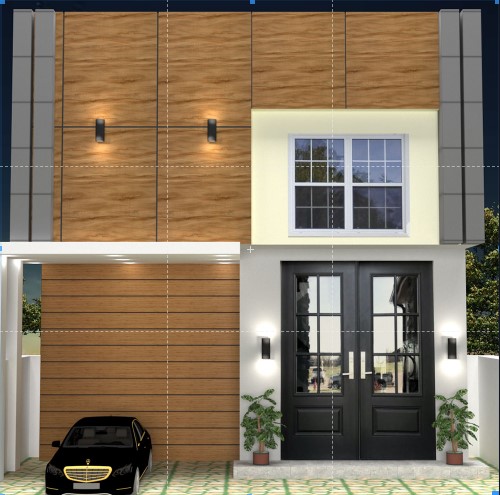

Reynoarch Wpc Louvers Curvy Trio + Panel

Reynobond india

₹170

Reynoarch Wpc Louvers 3 Flute Trio + Panel

Reynobond india

₹170

Reynoarch Ra-504 BETON SMOKE RUSTIC ACP Thickness 30mm , Size 2.5 x 8

Reynobond india

₹200

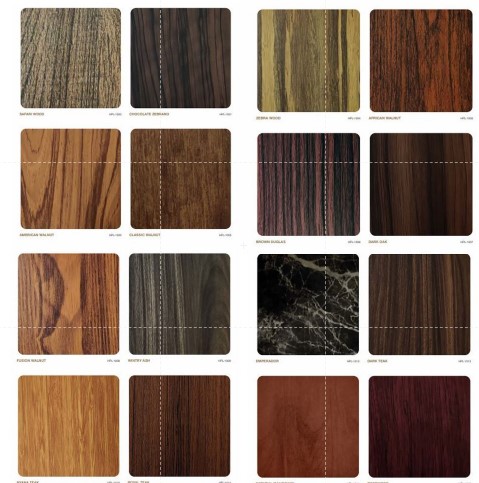

Facade HPL Series Plain Panel 6 mm Single Side

Reynobond india

₹156

Facade HPL Series Panel 6mm Double Side

Reynobond india

₹200

Facade HPL Series Panel 6mm Single Side

Reynobond india

₹175

Services & Tools

Comprehensive services and tools to support your Zinc Cladding project needs

No active Tools & Services currently

Product Comparison

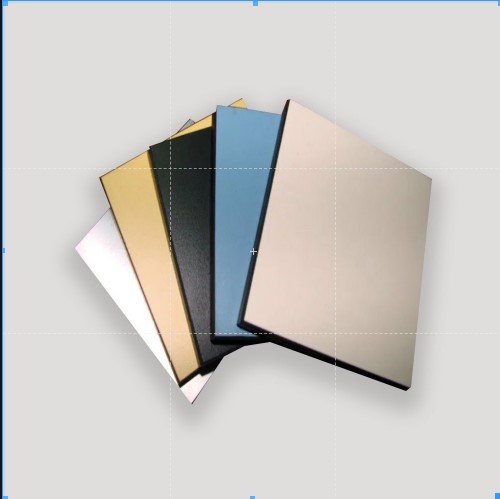

Complete Technical Specifications for Reynobond india REYNOARCH ZINC COMPOSITE PANEL--QUARTZ ZINC

| Property | Value | Unit |

|---|---|---|

| Product Code | — | kg/m² |

| Panel Thickness | — | mm |

| Aluminum Skin Thickness | — | mm |

| Panel Size | — | Width × Length in mm |

| Core Type | — | — |

| Surface Finish / Coating | — | — |

| Surface Color / Pattern | — | — |

| Gloss Level | — | — |

| Applications / Recommended Use | — | — |

| Certification & Standards Compliance | — | — |

| Top Skin | — | mm |

| Core Thickness | — | mm |

| Bottom Skin | — | mm |

Product Documents & Downloads

No documents available for this product