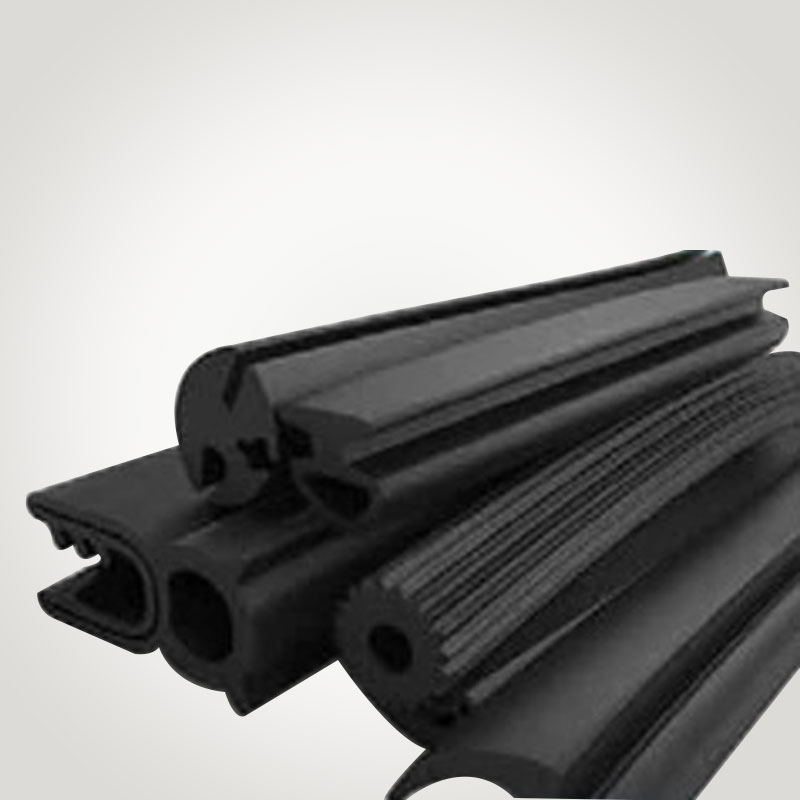

EPDM / TPE Rubber Profile – ORPL 5361 Gasket Osaka Rubber Pvt Ltd.

High Durability Rust Proof Superior Quality Excellent Weather Resistance Perfect Sealing with Glass, Window, or Door Frames Recyclable Cost-Effective Design Flexibility Lightweight Wide Service Temperature Range Easy to Process

Product manufacturer

Osaka Rubber Pvt Ltd.Product Category

Gasket

Osaka Rubber Pvt Ltd. Gasket EPDM / TPE Rubber Profile – ORPL 5361

High Durability Rust Proof Superior Quality Excellent Weather Resistance Perfect Sealing with Glass, Window, or Door Frames Recyclable Cost-Effective Design Flexibility Lightweight Wide Service Temperature Range Easy to Process

Loading specs...

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Osaka Rubber Pvt Ltd.

Osaka Rubber Pvt Ltd.

No other products available from this brand

Services & Tools

Comprehensive services and tools to support your Gasket project needs

No active Tools & Services currently

Product Comparison

Complete Technical Specifications for Osaka Rubber Pvt Ltd. EPDM / TPE Rubber Profile – ORPL 5361

| Property | Value | Unit |

|---|---|---|

| Product Name | EPDM / TPE Rubber Profile – ORPL 5361 | — |

| Product Code | ORPL 5361 | — |

| Material Type | EPDM Rubber / Thermo-Plastic Rubber | — |

| Thickness | 1.5 | mm |

| Features | High Durability, Rust Proof, Superior Quality, Excellent Weather Resistance, Perfect Sealing with Glass, Window, or Door Frames, Recyclable, Cost and performance, Design Flexibility, Weight Reduction, Wide service temperature range, ease of processing | — |

| Application | glass, aluminum window, door sealing systems | — |

| Color | Black | — |

Product Documents & Downloads

No documents available for this product