Kansai Nerolac I Polyester Powder Power Coating Kansai Nerolac Paints Limited

Pure Polyester powders give excellent Exterior Durability / UV resistance along with superior colour & gloss retention. It can be used for components which could be subjected to outside exposure. Typical Applications: Air conditioner cabinets, Garden & Agriculture equipments, Auto components, DG Gensets, cycles etc.

Product manufacturer

Kansai Nerolac Paints LimitedProduct Category

Power Coating

Kansai Nerolac Paints Limited Power Coating Kansai Nerolac I Polyester Powder

Pure Polyester powders give excellent Exterior Durability / UV resistance along with superior colour & gloss retention. It can be used for components which could be subjected to outside exposure. Typical Applications: Air conditioner cabinets, Garden & Agriculture equipments, Auto components, DG Gensets, cycles etc.

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

Services & Tools

Comprehensive services and tools to support your Power Coating project needs

Product Comparison

Complete Technical Specifications for Kansai Nerolac Paints Limited Kansai Nerolac I Polyester Powder

| Property | Value | Unit |

|---|---|---|

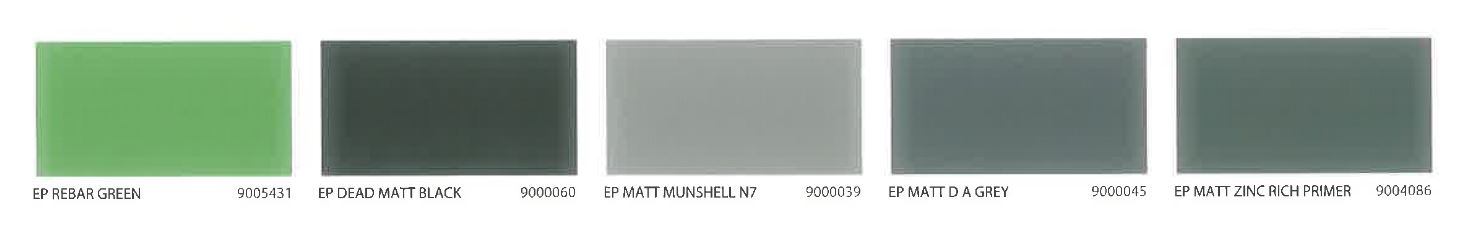

| Product Name | Pp Lb Wr Coke Red, Glossy Lsl Aircraft Blue, Pp S/g Mj Ral 6037, Pp S/g Mj Ral 6024, Pp Glossy Canopy Green, Nerocoat Pp Sd Cummins Green, Pp Matt Olive Green Isc 220, Pp Glossy Cloud Grey, Pp S/g Ral 7004, Ikea Gray No.28 Powder Metal, Pp S/g Sd Ral 7022 (P), Pp Cnhc Grey, Pp Gl Dark Dink Agro Grey, Pp Glossy Ken Ral 8011, Pp S/g Ken Brown Ral 8014, Pp Glossy Tvs Jet Black, Pp Mark Satin Black, Pp Matt Black, Pp Spl Matt Black (Bc), Pp New Bajaj Silver, Pp Met Sd Vernier Grey, Pp Met Tsa Silver, Pp S/g Brass Gold | — |

| Code | 9004024, 9005821, 9005826, 9005827, 9003126, 9006030, 9005389, 9004120, 9005742, 9005931, 9004956, 9003556, 9005028, 9005876, 9005655, 9004875, 9003996, 9001116, 9003663, 9002800, 9005600, 9004873, 9002966 | — |

| Flexibility | Excellent | — |

| Hardness | Excellent | — |

| Impact Resistance | Excellent | — |

| Overbake Resistance | Very Good | — |

| Chemical Resistance | Very Good | — |

| Corrosion Resistance | Very Good | — |

| Weather Resistance | Very Good | — |

| Baking Schedule | 200°C / 10–15 min | °C |

| Dry Film Thickness | 50 - 60 | microns |

| Gloss - Smooth Finish | 5 - 95 | — |

| Gloss - Structured Finish | 10 - 30 | — |

| Adhesion | Excellent (GT-0) | — |

| Pencil Hardness | 2 | H |

| Direct Impact Resistance - Smooth Powders | 150 | kg.cm |

| Direct Impact Resistance - Structured Powders | 40 - 150 | kg.cm |

| Salt Spray Test | 500 - | hrs |

| UV Exposure after 500 hrs (ASTM G-154) | Good | — |

| Application For | Exterior Purpose | — |

Product Documents & Downloads

No documents available for this product