Jindal I Aluminum Extrusion I Sliding Window sections(Deluxe) Aluminum Extrusion Jindal Aluminium

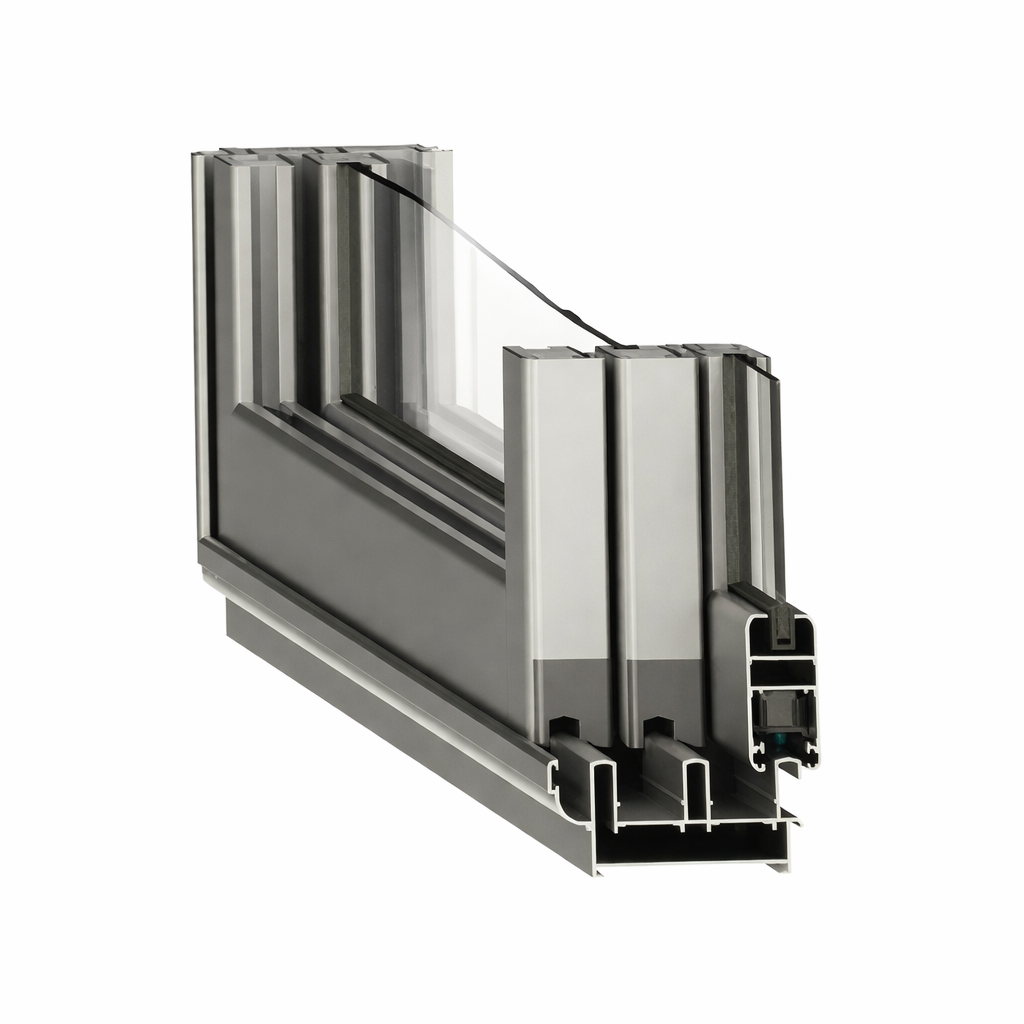

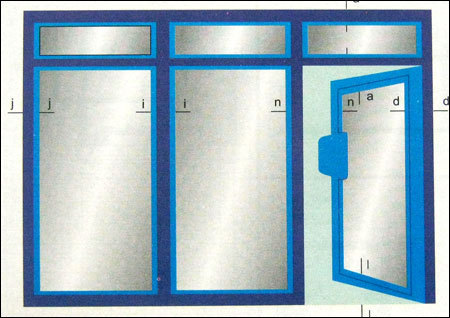

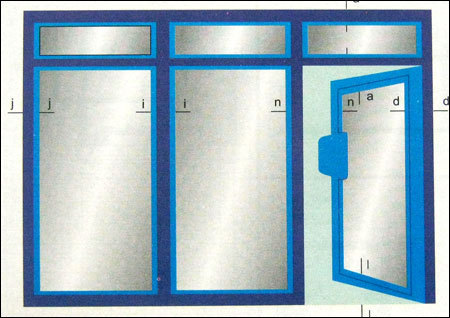

Jindal Aluminium Sliding Window Sections (Deluxe) are premium aluminium extrusion profiles designed for smooth-operating, high-performance sliding window systems. These deluxe sections combine refined aesthetics with enhanced strength and functionality, making them ideal for modern residential and commercial buildings. Manufactured from high-grade aluminium alloys using precision extrusion technology, Jindal deluxe sliding window profiles provide excellent dimensional accuracy, robust construction, and superior surface finish. The system is engineered to support larger shutters, improved load capacity, and smooth sliding action with advanced hardware and roller mechanisms.

Product manufacturer

Jindal AluminiumProduct Category

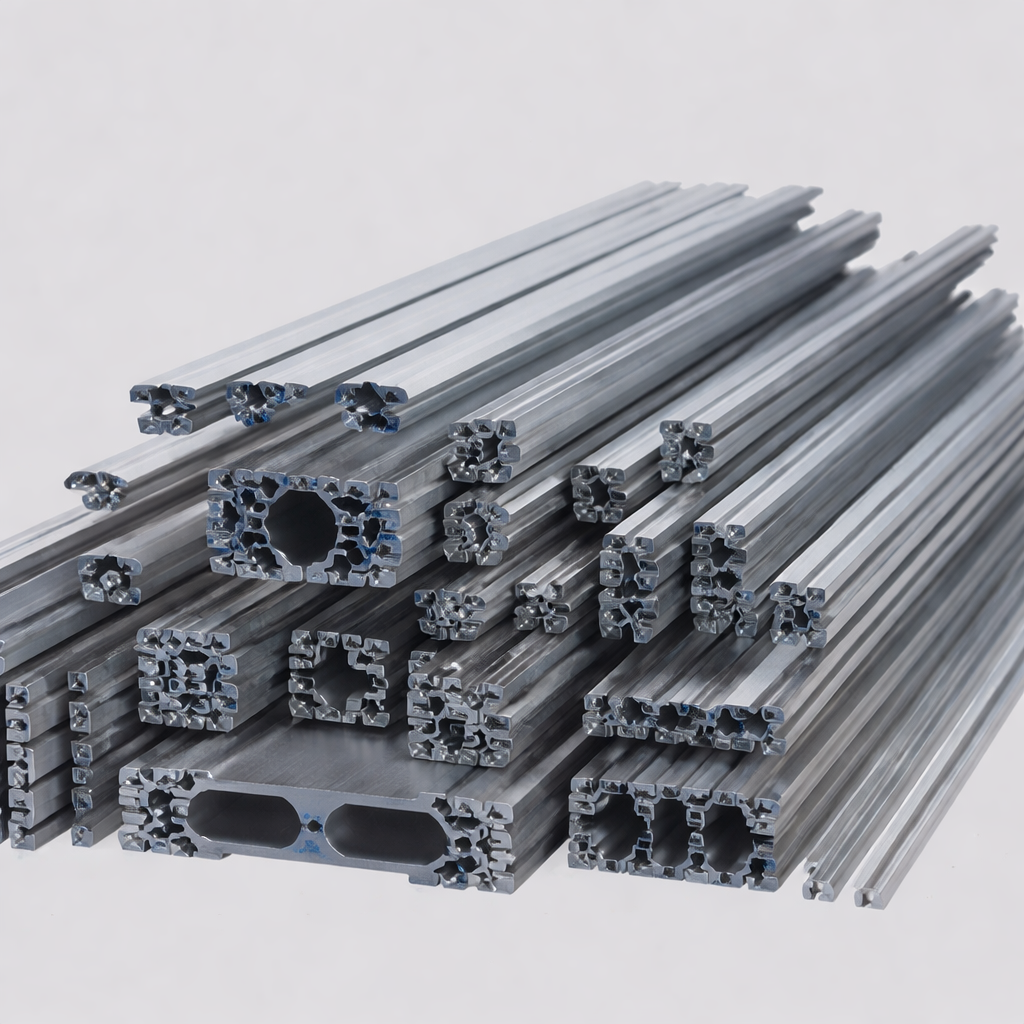

Aluminum Extrusion

Jindal Aluminium Aluminum Extrusion Jindal I Aluminum Extrusion I Sliding Window sections(Deluxe)

Jindal Aluminium Sliding Window Sections (Deluxe) are premium aluminium extrusion profiles designed for smooth-operating, high-performance sliding window systems. These deluxe sections combine refined aesthetics with enhanced strength and functionality, making them ideal for modern residential and commercial buildings. Manufactured from high-grade aluminium alloys using precision extrusion technology, Jindal deluxe sliding window profiles provide excellent dimensional accuracy, robust construction, and superior surface finish. The system is engineered to support larger shutters, improved load capacity, and smooth sliding action with advanced hardware and roller mechanisms.

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Jindal Aluminium

Jindal Aluminium

Jindal I Aluminum Extrusion I General Miscellaneous

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Architectural Miscellaneous

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Casement Window section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Curtain Wall Section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Display section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Door Cum Partition Sections

Jindal Aluminium

₹325

Services & Tools

Comprehensive services and tools to support your Aluminum Extrusion project needs

Product Comparison

Complete Technical Specifications for Jindal Aluminium Jindal I Aluminum Extrusion I Sliding Window sections(Deluxe)

| Property | Value | Unit |

|---|---|---|

| Code | 21419, 21456, 21714, S6408 | — |

| Application | Sliding Window Sections (Deluxe) | — |

| Industrial | Building and Construction | — |

| weight | any | — |

Product Documents & Downloads

Related Aluminum Extrusion

Jindal I Aluminum Extrusion I Door Cum Partition Sections

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I NorthLight Glazing Bars S Shoes

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Sliding Window Sections

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I General Miscellaneous

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Casement Window section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Curtain Wall Section

Jindal Aluminium

₹325