Jindal I Aluminum Extrusion I NorthLight Glazing Bars S Shoes Aluminum Extrusion Jindal Aluminium

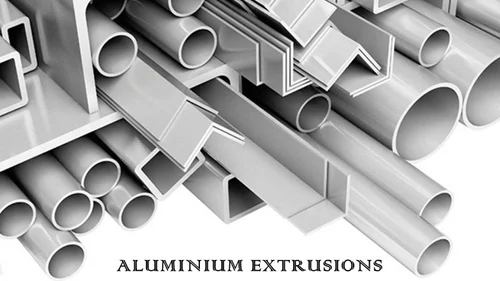

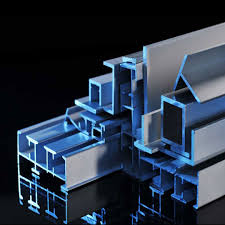

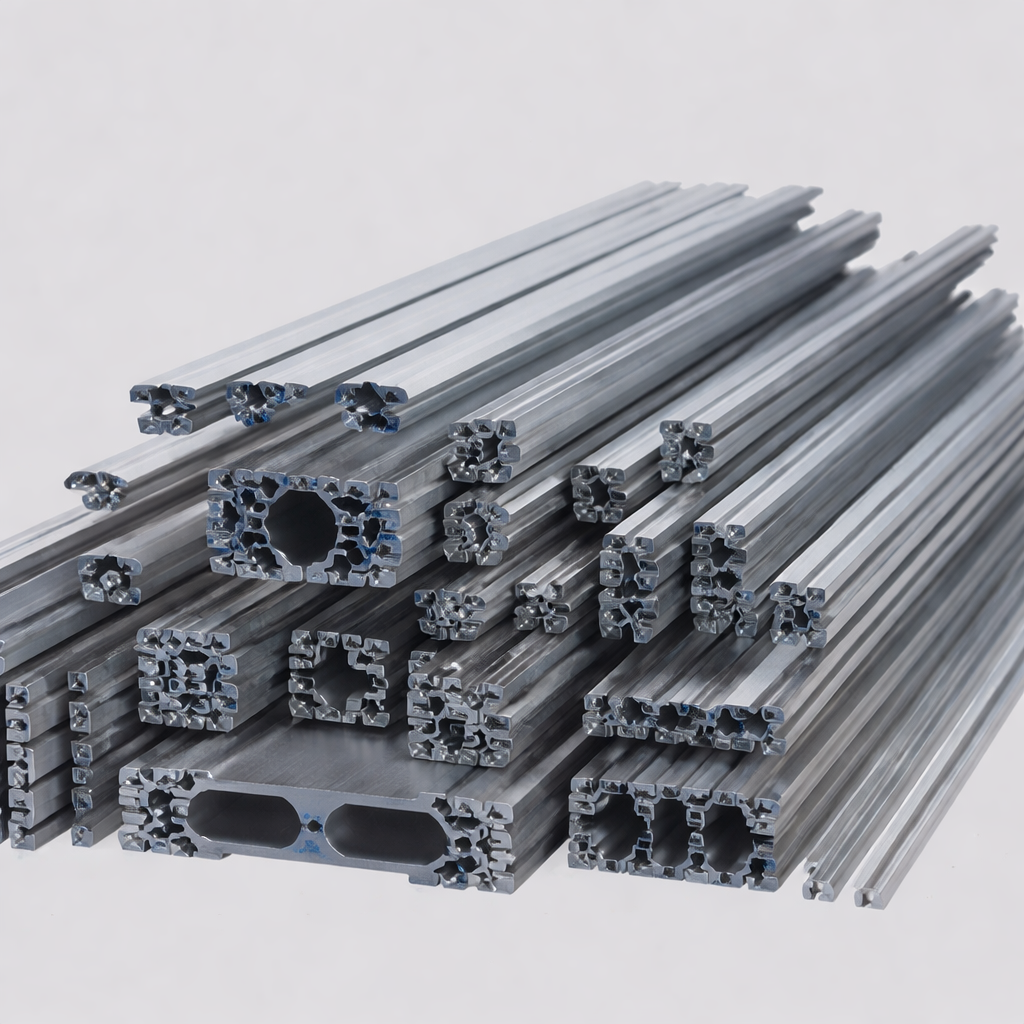

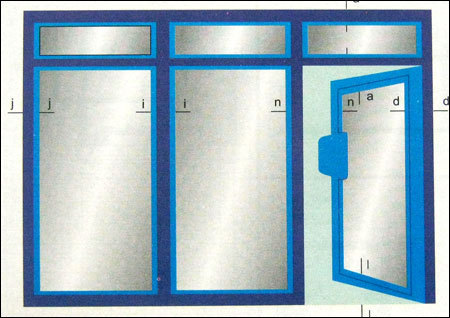

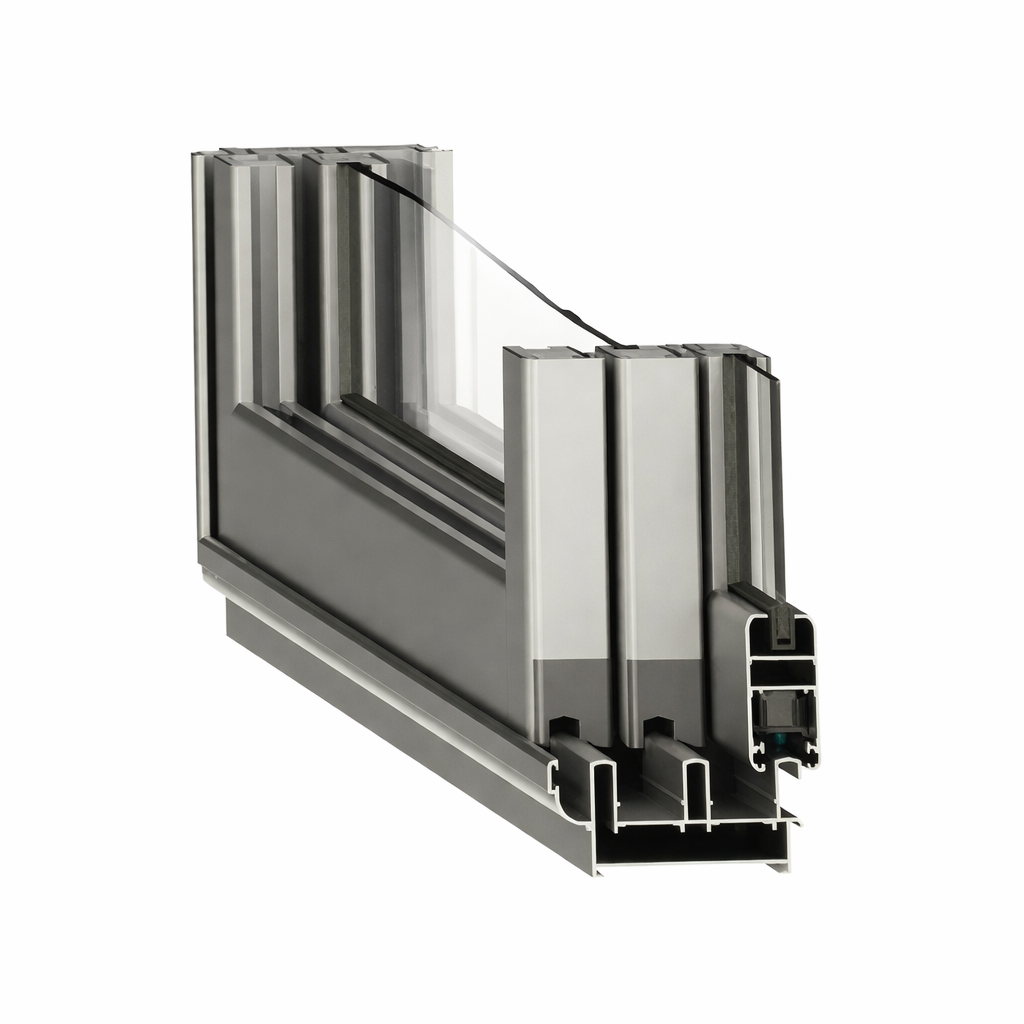

Jindal Aluminium Northlight Glazing Bars & Shoes are specially engineered aluminium extrusion sections used in industrial and architectural northlight roofing and skylight systems. These profiles provide reliable structural support, precise glass holding, and effective weatherproofing for large-span daylighting applications. Manufactured from high-quality aluminium alloys using advanced extrusion technology, Jindal northlight glazing bars and shoes ensure high load-bearing capacity, accurate dimensions, and long-term durability. The system is designed to securely support glass or polycarbonate panels while allowing controlled natural light entry and efficient drainage

Product manufacturer

Jindal AluminiumProduct Category

Aluminum Extrusion

Jindal Aluminium Aluminum Extrusion Jindal I Aluminum Extrusion I NorthLight Glazing Bars S Shoes

Jindal Aluminium Northlight Glazing Bars & Shoes are specially engineered aluminium extrusion sections used in industrial and architectural northlight roofing and skylight systems. These profiles provide reliable structural support, precise glass holding, and effective weatherproofing for large-span daylighting applications. Manufactured from high-quality aluminium alloys using advanced extrusion technology, Jindal northlight glazing bars and shoes ensure high load-bearing capacity, accurate dimensions, and long-term durability. The system is designed to securely support glass or polycarbonate panels while allowing controlled natural light entry and efficient drainage

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Jindal Aluminium

Jindal Aluminium

Jindal I Aluminum Extrusion I General Miscellaneous

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Architectural Miscellaneous

Jindal Aluminium

₹325

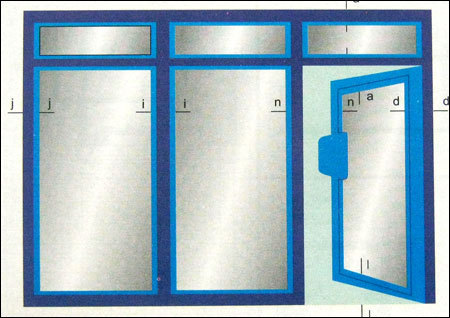

Jindal I Aluminum Extrusion I Casement Window section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Curtain Wall Section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Display section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Door Cum Partition Sections

Jindal Aluminium

₹325

Services & Tools

Comprehensive services and tools to support your Aluminum Extrusion project needs

Product Comparison

Complete Technical Specifications for Jindal Aluminium Jindal I Aluminum Extrusion I NorthLight Glazing Bars S Shoes

| Property | Value | Unit |

|---|---|---|

| Code | 22530, 22534, 22536, 22537 | — |

| Application | NorthLight Glazing Bars S Shoes | — |

| Industrial | Building and Construction | — |

| weight | any | — |

Product Documents & Downloads

Related Aluminum Extrusion

Jindal I Aluminum Extrusion I Door Cum Partition Sections

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Sliding Window Sections

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I General Miscellaneous

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Casement Window section

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Sliding Window sections(Deluxe)

Jindal Aluminium

₹325

Jindal I Aluminum Extrusion I Curtain Wall Section

Jindal Aluminium

₹325