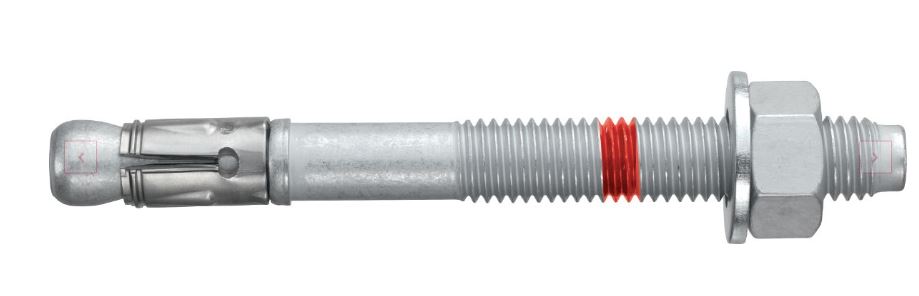

HSTM10X90 General Purpose Anchor Fasteners HILTI

High loading capacity force-controlled expansion suitable for tension zone suitable for shock loading fire prevention assessment pre-assembled with nut and washer save time cold formed

Product manufacturer

HILTIProduct Category

General Purpose Anchor Fasteners

HILTI General Purpose Anchor Fasteners HSTM10X90

High loading capacity force-controlled expansion suitable for tension zone suitable for shock loading fire prevention assessment pre-assembled with nut and washer save time cold formed

Loading specs...

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

Services & Tools

Comprehensive services and tools to support your General Purpose Anchor Fasteners project needs

No active Tools & Services currently

Product Comparison

Complete Technical Specifications for HILTI HSTM10X90

| Property | Value | Unit |

|---|---|---|

| Product Code | HST M10X90 | — |

| Features | High loading capacity, force-controlled expansion, suitable for tension zone, suitable for shock loading, fire prevention assessment, pre-assembled with nut and washer save time, cold formed | — |

| Application | Concrete, Tension zone, Corrosion resistance, shock, Close edge, Fire resistance Hilti Anchor programme, High corrosion resistance | — |

| Drill bit dia | 10 | mm |

| Anchor Length | 90 | mm |

| Thread Length ( HST) | 30 | mm |

| Width across nut flats | 17 | mm |

| Clearance hole diameter | 12 | mm |

| Min depth drill hole | 80 | mm |

| Effective embed depth | 80 | mm |

| Max fastenable thicknedd | 10 | mm |

| Min concrete thickness | 120 | mm |

| Drill bit | TE-CX-10 | — |

| Rec tightening torque | 45 | nm |

Product Documents & Downloads

No documents available for this product