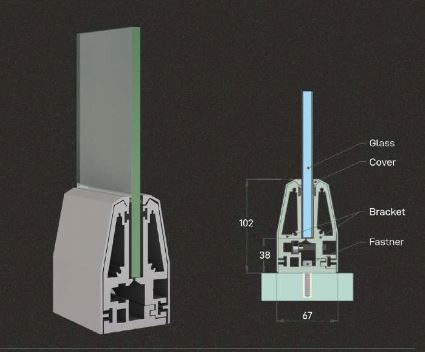

STEP BRACKET AND COVER ARB-002 Glass Railing H Line

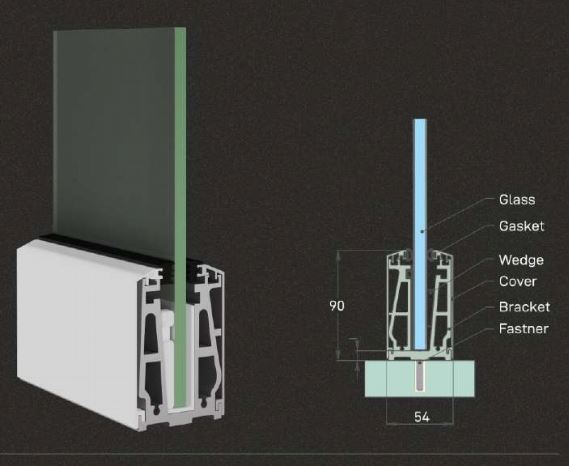

ARB-002 is a heavier, stronger base bracket system compared to ARB-001 (profile size: 90 mm height × 54 mm width).

Product manufacturer

H LineProduct Category

Glass Railing

H Line Glass Railing STEP BRACKET AND COVER ARB-002

ARB-002 is a heavier, stronger base bracket system compared to ARB-001 (profile size: 90 mm height × 54 mm width).

Loading specs...

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

Services & Tools

Comprehensive services and tools to support your Glass Railing project needs

No active Tools & Services currently

Product Comparison

Complete Technical Specifications for H Line STEP BRACKET AND COVER ARB-002

| Property | Value | Unit |

|---|---|---|

| Product Name | STEP BRACKET AND COVER ARB-002 | — |

| Material Grade | Aluminium Alloy 6063-T6 | — |

| Application | Indoor & Outdoor | — |

| Dimensions | — | mm |

| Glass Thickness | 12 | mm |

| Mounting Type | — | — |

| Glass Height | 24, 30, 36, 42 | inch |

| Surface Finish | Natural, Anodize, Powder Coating, Wooden Coating | — |

| Feature | — | — |

| Material Type | — | — |

| Length | 13, 16 | ft |

| Finish | — | — |

| Balcony Length | 10, 20, 30 | ft |

| Warranty | — | — |

Product Documents & Downloads

Loading documents...