Solid EPDM Rubber Gasket Fusion polymer Industries

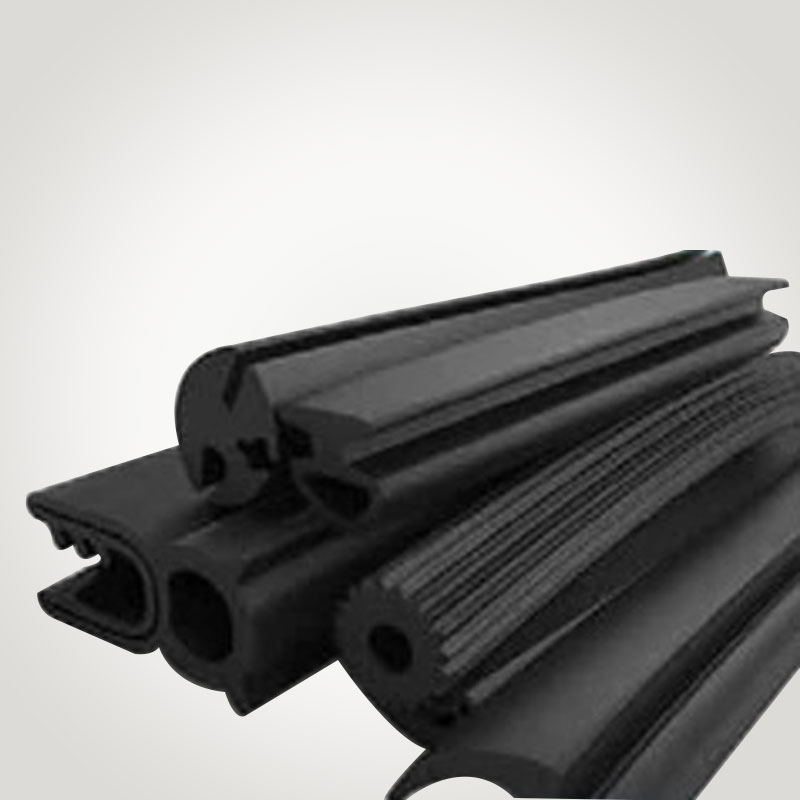

Solid EPDM Rubber Profiles are high-performance sealing solutions crafted from *Ethylene Propylene Diene Monomer (EPDM)* , a synthetic rubber known for its outstanding durability and versatility. These profiles are designed to perform in the most demanding environments, offering reliable, long-lasting sealing for a wide range of industrial applications.

Product manufacturer

Fusion polymer IndustriesProduct Category

Gasket

Fusion polymer Industries Gasket Solid EPDM Rubber

Solid EPDM Rubber Profiles are high-performance sealing solutions crafted from *Ethylene Propylene Diene Monomer (EPDM)* , a synthetic rubber known for its outstanding durability and versatility. These profiles are designed to perform in the most demanding environments, offering reliable, long-lasting sealing for a wide range of industrial applications.

Technical Specifications Summary

- Product Name

- Solid EPDM Rubber

- Product Code

- FPI : 047, FPI : 048 FPI : 042, FPI : 088

- Material Type

- Ethylene Propylene Diene Monomer (EPDM)

- Thickness

- 0.5, 1, 1.5, 2, 3, 4, 5, 6 mm

- Features

- Weather, Ozone, and UV Resistance, Superior Elasticity and Flexibility, Temperature Resilience, Reliable Sealing Performance

- Application

- Construction Industry, Automotive, Industrial Sectors, Customization

More Products from Fusion polymer Industries

Fusion polymer Industries

Services & Tools

Comprehensive services and tools to support your Gasket project needs

Complete Technical Specifications for Fusion polymer Industries Solid EPDM Rubber

| Property | Value | Unit |

|---|---|---|

| Product Name | Solid EPDM Rubber | — |

| Product Code | FPI : 047, FPI : 048 FPI : 042, FPI : 088 | — |

| Material Type | Ethylene Propylene Diene Monomer (EPDM) | — |

| Thickness | 0.5, 1, 1.5, 2, 3, 4, 5, 6 | mm |

| Features | Weather, Ozone, and UV Resistance, Superior Elasticity and Flexibility, Temperature Resilience, Reliable Sealing Performance | — |

| Application | Construction Industry, Automotive, Industrial Sectors, Customization | — |

Product Documents & Downloads

No documents available for this product

Quality Assurance

We follow 4-point checks at our factory for quality assurance of Gasket

Raw materials check

As soon as the raw materials come into production units, they undergo test at our labs to get their properties checked, passing which they go to the store.

Product Check

The product thus manufactured, undergoes the most stringent test according to global standards, passing which it qualifies for dispatch.

Check at the manufacturing stage

At different stages of manufacturing, tests are done to validate if the purpose of a particular stage has been served or not. For e.g at the pre-treatment stage it is checked whether degreasing or deoxidizing of the aluminium coil has properly taken place or not.

Post production check

Before being dispatched, thorough visual inspection is done to check product tolerances and any other kind of manufacturing defect.