Dark Blue Aluminium Composite Panel ACP (Aluminium composite panel) Reynobond india

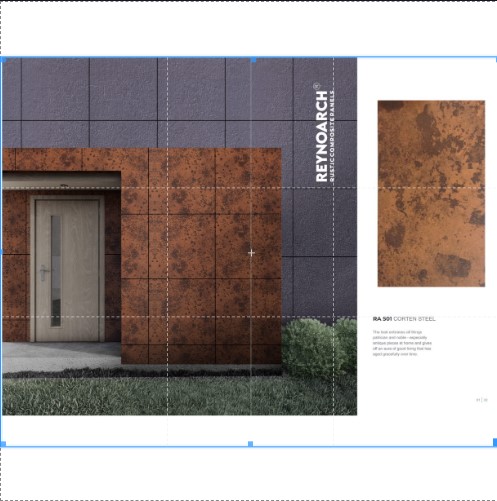

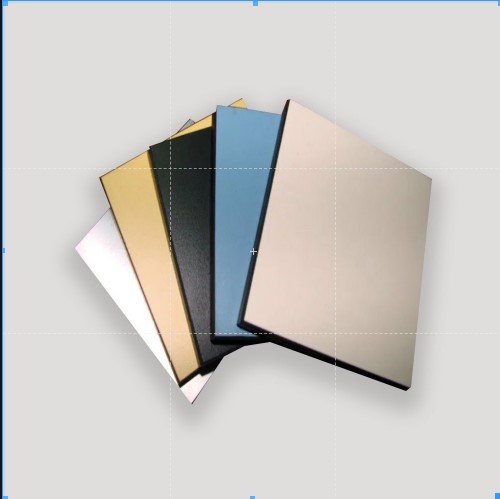

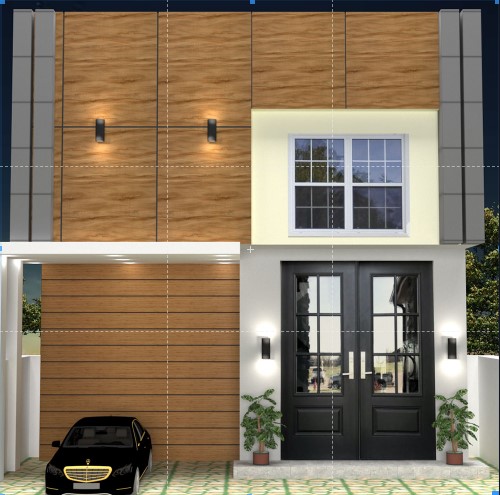

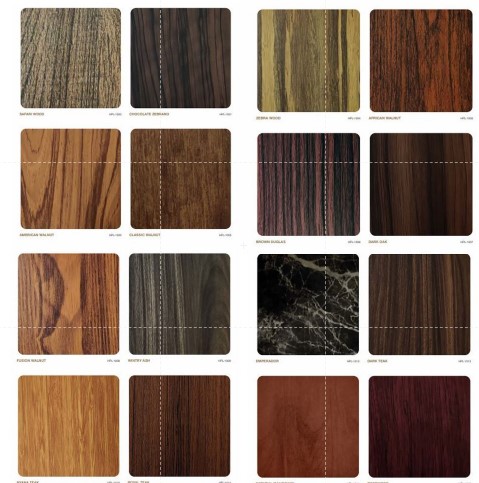

Reynoarch composite panels consist of two coated aluminium sheets that are laminated to both sides of a PE core. Flatness, lightweight, minimal expansion, high corrosion and weather resistance are some of the advantages that make it an outstanding product. Advantage Cost-Effective: Easy And Quick Installation And Maintenance Highly UV And Weather Resistant, Easy To Fabricate And Bend: Freedom In Design For Unusual Shape Features: Flatness Excellent flatness derived from the continuous lamination process Color Uniformity The coil coating process ensures complete color consistency Rigidity Reynoarch is rigid and lightweight Workability Easy to process with ordinary fabrication machines and tools Ecology Reynoarch and environmentally friendly

Product manufacturer

Reynobond indiaProduct Category

ACP (Aluminium composite panel)

Reynobond india ACP (Aluminium composite panel) Dark Blue Aluminium Composite Panel

Reynoarch composite panels consist of two coated aluminium sheets that are laminated to both sides of a PE core. Flatness, lightweight, minimal expansion, high corrosion and weather resistance are some of the advantages that make it an outstanding product. Advantage Cost-Effective: Easy And Quick Installation And Maintenance Highly UV And Weather Resistant, Easy To Fabricate And Bend: Freedom In Design For Unusual Shape Features: Flatness Excellent flatness derived from the continuous lamination process Color Uniformity The coil coating process ensures complete color consistency Rigidity Reynoarch is rigid and lightweight Workability Easy to process with ordinary fabrication machines and tools Ecology Reynoarch and environmentally friendly

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Reynobond india

Reynobond india

Reynoarch Wpc Louvers Curvy Trio + Panel

Reynobond india

₹170

Reynoarch Wpc Louvers 3 Flute Trio + Panel

Reynobond india

₹170

Reynoarch Ra-504 BETON SMOKE RUSTIC ACP Thickness 30mm , Size 2.5 x 8

Reynobond india

₹200

Facade HPL Series Plain Panel 6 mm Single Side

Reynobond india

₹156

Facade HPL Series Panel 6mm Double Side

Reynobond india

₹200

Facade HPL Series Panel 6mm Single Side

Reynobond india

₹175

Services & Tools

Comprehensive services and tools to support your ACP (Aluminium composite panel) project needs

Product Comparison

Complete Technical Specifications for Reynobond india Dark Blue Aluminium Composite Panel

| Property | Value | Unit |

|---|

Product Documents & Downloads

No documents available for this product