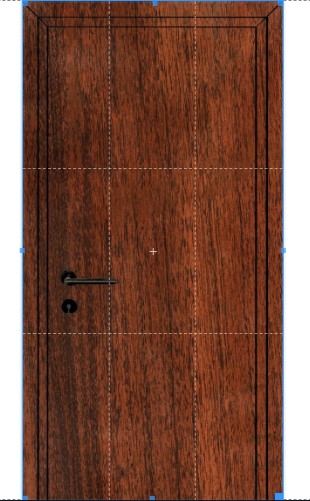

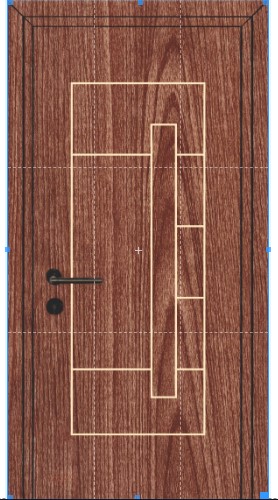

Alstone WPC Prelam Doors Hybrid AMD24, Standard Size, Thickness 25 Mm Doors Reynobond india

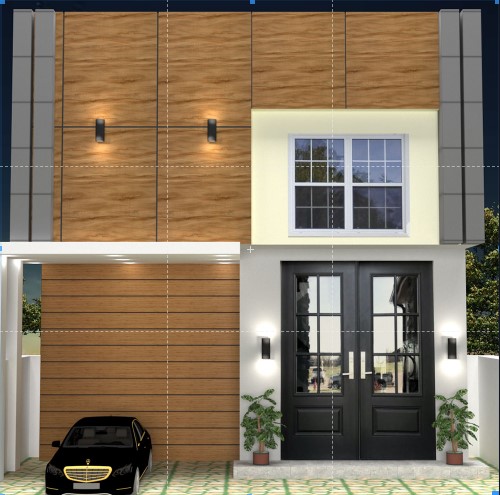

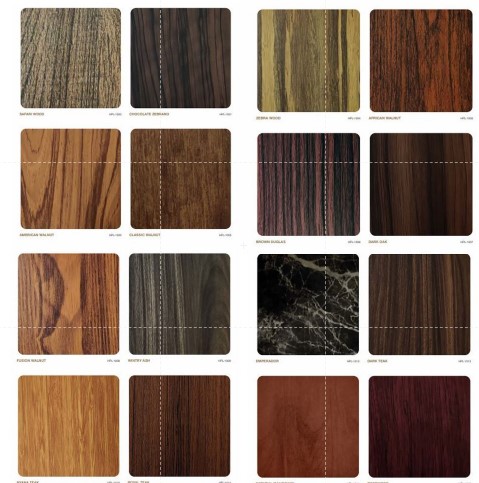

Alstone Pre-Laminated Solid doors are made of high quality Wood Polymer Composites to make them exceptionally durable and dimensionally stable with excellent finishing properties. Our Decorative Doors are long lasting and retain their great looks throughout their life. Alstone Pre-Laminated Solid door is ready to use doors These doors are made with WPC core laminated with European decorative foils suitable of residential and commercial application. It is available in BSL (Both Side Lamination) with multiple sizes and thickness. Alstone WPC decorative Doors are known for its Unmatched Quality & Endless Application has brought revolution in the Indian Door Industry. With intent to offer best quality innovative doors, “WPC Door” is the latest avatar for Door Industry. This novel application will add wings to your Doors in both commercial and residential segment.

Product manufacturer

Reynobond indiaProduct Category

Doors

Reynobond india Doors Alstone WPC Prelam Doors Hybrid AMD24, Standard Size, Thickness 25 Mm

Alstone Pre-Laminated Solid doors are made of high quality Wood Polymer Composites to make them exceptionally durable and dimensionally stable with excellent finishing properties. Our Decorative Doors are long lasting and retain their great looks throughout their life. Alstone Pre-Laminated Solid door is ready to use doors These doors are made with WPC core laminated with European decorative foils suitable of residential and commercial application. It is available in BSL (Both Side Lamination) with multiple sizes and thickness. Alstone WPC decorative Doors are known for its Unmatched Quality & Endless Application has brought revolution in the Indian Door Industry. With intent to offer best quality innovative doors, “WPC Door” is the latest avatar for Door Industry. This novel application will add wings to your Doors in both commercial and residential segment.

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

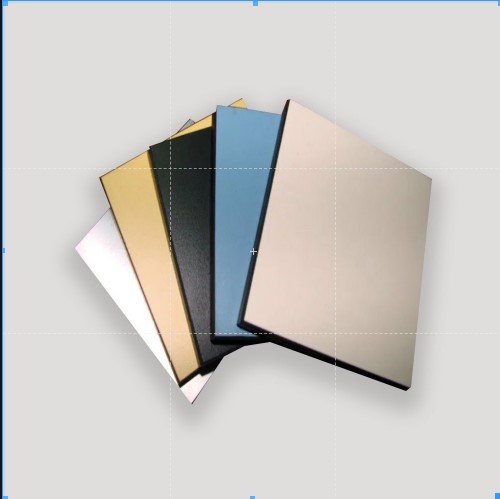

More Products from Reynobond india

Reynobond india

Reynoarch Wpc Louvers Curvy Trio + Panel

Reynobond india

₹170

Reynoarch Wpc Louvers 3 Flute Trio + Panel

Reynobond india

₹170

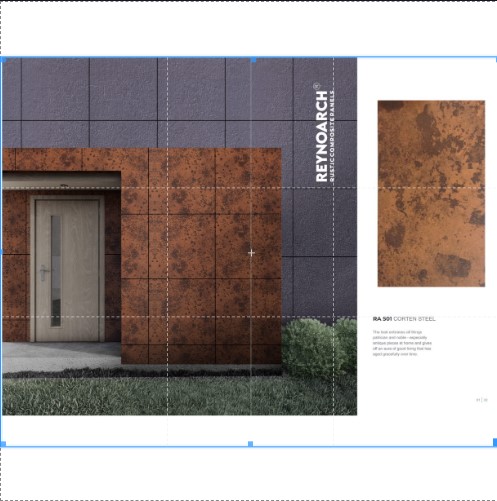

Reynoarch Ra-504 BETON SMOKE RUSTIC ACP Thickness 30mm , Size 2.5 x 8

Reynobond india

₹200

Facade HPL Series Plain Panel 6 mm Single Side

Reynobond india

₹156

Facade HPL Series Panel 6mm Double Side

Reynobond india

₹200

Facade HPL Series Panel 6mm Single Side

Reynobond india

₹175

Services & Tools

Comprehensive services and tools to support your Doors project needs

Product Comparison

Complete Technical Specifications for Reynobond india Alstone WPC Prelam Doors Hybrid AMD24, Standard Size, Thickness 25 Mm

| Property | Value | Unit |

|---|

Product Documents & Downloads

No documents available for this product

Related Doors

Alstone Wood Polymer Composite Sheet ECO

Reynobond india

₹257

Alstone WPC Routed Doors Eco ,Standard Size, Thickness 30 mm

Reynobond india

₹612

Alstone WPC Prelam Doors AMD 22,Standard Size, Thickness 35 Mm

Reynobond india

₹844

Alstone WPC Prelam Routed Doors,Standard Size, Thickness 25mm 30mm, 35 Mm

Reynobond india

₹844

Alstone WPC Prelam Doors Hybrid ,Standard Size, Thickness 35 mm

Reynobond india

₹794

Alstone WPC Routed Doors Eco ,Standard Size, Thickness 25 mm

Reynobond india

₹536