Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 Ft , Thickness 30 Mm interior partitions Reynobond india

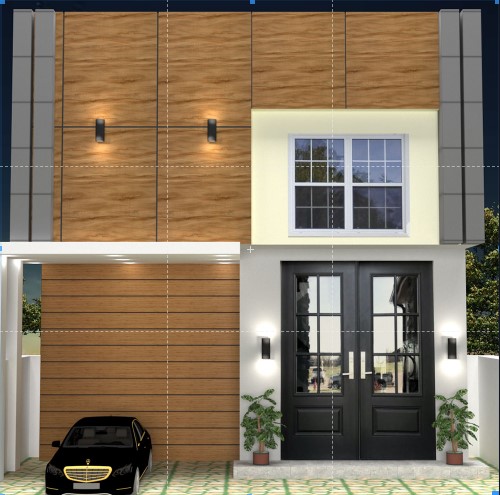

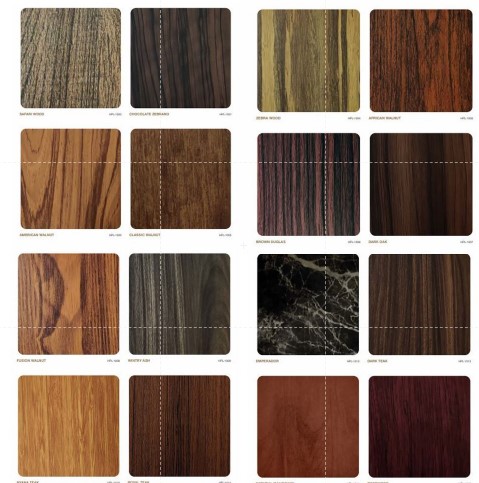

WPC is a modern and ecological composite material which is made of60% PVC, 30% rice & wheat husk and 10% calcium carbonate and additives. It is the best substitute of Plywood because of its strength and durability. The major advantage of WPC lies in the fact that it retains the best properties of wood while eliminating all the downsides which one may face with woods. For decades we have been cutting down trees to fulfil our need and demand of building products. The cost of the products made from plywood is too high. Along with the cost constraint there is limitation of colours available as well and the durability is also low. It is a versatile material with multitude application area. We can make all types of furniture using WPC like Modular furnishing, Bathroom vanities ,kitchen , cabinets , interior, partitioning ,shoe rack,wardrobes, cupboards, tables, chairs and any type of interior and exterior furniture.

Product manufacturer

Reynobond indiaProduct Category

interior partitions

Reynobond india interior partitions Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 Ft , Thickness 30 Mm

WPC is a modern and ecological composite material which is made of60% PVC, 30% rice & wheat husk and 10% calcium carbonate and additives. It is the best substitute of Plywood because of its strength and durability. The major advantage of WPC lies in the fact that it retains the best properties of wood while eliminating all the downsides which one may face with woods. For decades we have been cutting down trees to fulfil our need and demand of building products. The cost of the products made from plywood is too high. Along with the cost constraint there is limitation of colours available as well and the durability is also low. It is a versatile material with multitude application area. We can make all types of furniture using WPC like Modular furnishing, Bathroom vanities ,kitchen , cabinets , interior, partitioning ,shoe rack,wardrobes, cupboards, tables, chairs and any type of interior and exterior furniture.

Suppliers & Dealers

0 dealers found

Applicators & Contractors

0 installers found

More Products from Reynobond india

Reynobond india

Reynoarch Wpc Louvers Curvy Trio + Panel

Reynobond india

₹170

Reynoarch Wpc Louvers 3 Flute Trio + Panel

Reynobond india

₹170

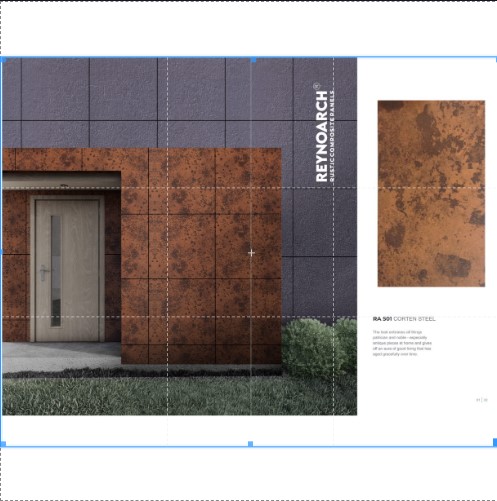

Reynoarch Ra-504 BETON SMOKE RUSTIC ACP Thickness 30mm , Size 2.5 x 8

Reynobond india

₹200

Facade HPL Series Plain Panel 6 mm Single Side

Reynobond india

₹156

Facade HPL Series Panel 6mm Double Side

Reynobond india

₹200

Facade HPL Series Panel 6mm Single Side

Reynobond india

₹175

Services & Tools

Comprehensive services and tools to support your interior partitions project needs

Product Comparison

Complete Technical Specifications for Reynobond india Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 Ft , Thickness 30 Mm

| Property | Value | Unit |

|---|

Product Documents & Downloads

No documents available for this product

Related interior partitions

Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 ft , Thickness 12mm

Reynobond india

₹206

Alstone Wood Polymer Composite Sheet ECO , Size 8x4 ft , Thickness 12mm

Reynobond india

₹171

Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 ft , Thickness 25mm

Reynobond india

₹380

Alstone Wood Polymer Composite Sheet Hybrid , Size 8x4 ft , Thickness 8mm

Reynobond india

₹146

Alstone Hybrid Board Wpc

Reynobond india

₹150